- YOUWEI GROUP /

- TECHNOLOGICAL /

-

PRODUCT

-

SOCIAL RESPONSIBILITY

-

INVESTOR

- JOIN /

The new material technology of LED light-curing coating avoids the harmful thinner of solvent-based high VOC s emission from the source of the formula. The coating is irradiated with energy-saving and environmentally friendly LED light source and can be completely cured in a few seconds. Due to the fast speed of LED light curing coating, labor saving, high efficiency, flexible spraying to adapt to shaped workpieces, excellent film terminal performance, and the 100% solid content and single component characteristics of LED light curing coating can achieve the recycling of paint mist, At the same time, further integration of new coating materials and automated coating equipment will significantly reduce the overall cost of coating.

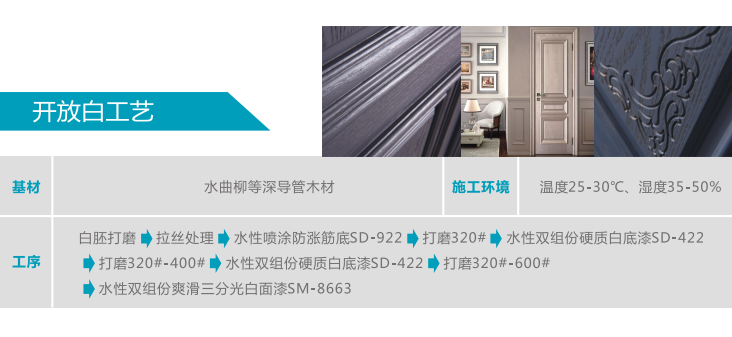

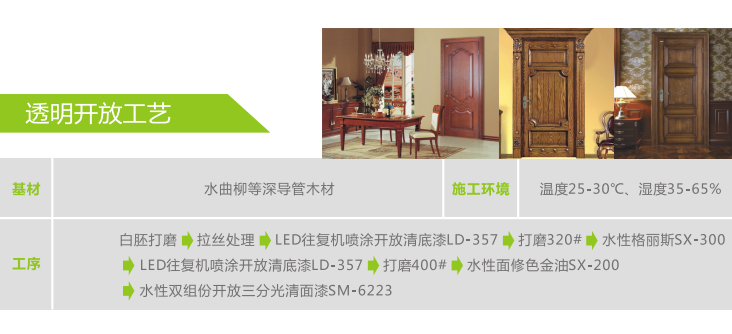

Wood paint development and process specifications

This technical solution does not use petroleum-based chemical solvents throughout the process, achieving environmental protection and zero emissions of VOCs from the source, avoiding the high-cost passive environmental protection of the VOCs tail of traditional oily coatings; solving the slow drying and catching up of traditional single and double component waterborne coatings Water leveling and curing require the use of auxiliary equipment and space extension, resulting in excessive energy consumption and cumbersome wiring, inability to effectively balance the contradiction between forced water catching and ensuring the wood's organic moisture content, poor physical properties of the coating, short activation period of the two-component, etc. Problem; Solve the universality of UV light curing coating workpieces, and achieve a win-win situation in product quality and production efficiency.

Industrial Coating R&D